ST59 Climbing Drum Peel Jig

Typically this jig is used to test aluminium faced honeycomb cored structural panels used in the aerospace and similar industries. The test measures the force required to peel the facing sheet from the core, thus testing the effectiveness of the adhesive joint. An alternative use is for testing the adhesive strength of bonded assemblies. A flat steel plate is supplied with the fixture to support this type of sample in accordance with the ASTM standard.

To perform the test, one end of one of the facing panels is attached to an eccentric roller grip attached to the loadcell of the machine. The opposite end of the opposing facing panel is attached to the eccentric roller on the drum. The drum has two steel bands wrapped around it’s circumference, these are attached to the lower crosshead of the machine. As the upper crosshead is moved away the bands rotate the drum which climbs up the panel, peeling off the facing sheet.

Laminated samples are tested in the same way after mounting the sample on to the carrier plate. All parts are either stainless steel or plated for corrosion resistance.

Full Description

Sample Size

76mm wide, 305mm long, typically 12.7mm thick.

Sample Type

Sandwich construction panels.

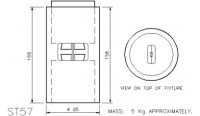

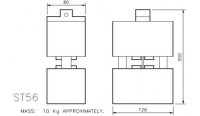

Weight

4 kg.

Accessories

Steel backing plate for laminated assemblies.