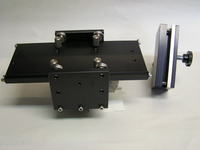

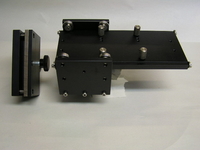

ST17 90 Degree Peel Jig

The jig consists of table mounted on virtually frictionless rollers. The sample is adhered to the table and one end clamped in the vice. The vice is connected to the load cell and moving cross head of the machine. As the machine cross head moves up the sample is peeled off the table. The 90 degree angle is maintained as the table moves across on it’s rollers. Some customers like to control the speed of the table by linking it to the moving cross head of the machine. A kit consisting of four pulleys, their mounting brackets and a drive cord is available for this purpose. This does not form part of the standard fixture. When fitted the drive cord is tied to the moving cross head, not the load cell. This ensures the table moves at the machine cross head speed but does not influence the peel force.

If a laminate is being tested or if the application demands the sample is peeled from a specific surface, the table is equipped with clamping screws to hold a separate substrate. Substrates up to 80mm wide can be clamped to the surface of the table.

Full Description

MAXIMUM LOAD

1kN.

SAMPLE SIZE

Samples and substrates up to 80mm wide. The vice will accept samples up to 5mm thick.

SAMPLE TYPE

Adhesive backed tapes, laminated sheet, raw adhesive.

WEIGHT

2 Kg approximately

ACCESSORIES

Kit to provide mechanical cord drive from the machine cross head. S17022