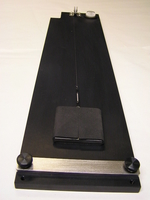

ST16/2 BS2782 Pt 8 1984 CO-FFICIENT OF SLIDING FRICTION

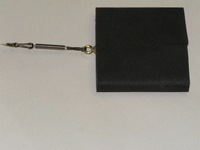

Designed to measure the coefficient of friction between two pieces of film, or other samples and substrates, at a constant speed with a fixed pressure between the surfaces. The jig consists of a long flat bed and a sled. The sled is moved along the bed by the testing machine. The sled connects to the machine load cell via a thread passing over a low friction pulley. Sled speed is therefore identical to machine speed, and friction load is measured directly. A spring assembly is supplied with this version of the fixture but this need not be used if the static co-efficient is not important, refer to the standard for the use of this item. A longer baseplate is supplied with this model for customers who prefer the longer test length as used in older versions of the BS specification.

The baseplate has a clamp at the rear to hold the sample during the test, the sample can also be taped to the baseplate if required. The sled is are designed to give the correct pressure between the two halves of the sample as defined by the relevant standard. Samples are fixed to the sled using conventional or double sided adhesive tape. A bi-directional spirit level and adjustable feet allow the baseplate to be levelled.

Full Description

Sample Size

120mm x 120mm for the sled, for the baseplate 80mm x 200 mm.

Sled to weigh 200gms +/- 2 gms.

Sample Type

Plastic film, laminates or any flat substrate and sample.

Weight

4.5 Kg

Part Numbers

EN ISO 8295 2004 and BS2782 part 8 Method 824A:1996 ST16/2